Upright Convection Oven

Oven, Forced Convection, Temperature Range ambient +10 °C to +250 °C, Chamber Volume 250, 372, 655 liters

catalog-jsof-t-upright-oven-eng.pdf |

|

Download Data Sheet |

JSOF-400T | JSOF-700T |

|

|

|

Upright Oven |

250 Liter |

372 Liter | 655 Liter |

General Specifications

|

Heating |

Forced Air Convection |

|

|

Dual heating chamber system |

|

Temp. Range |

ambient + 10°C ~ 250°C |

|

Accuracy |

± 0.3°C at 120°C (JSOF-250T) |

|

Uniformity |

± 1.5°C at 120°C (JSOF-250T) |

|

Control |

JIC-CON 5th GEN Microprocessor PID Controller |

|

Sensor |

Class A Pt-100 Ω Sensor |

|

Safety |

Over-Temperature Cut-Off |

|

|

Over Current Cut-Off |

|

Material |

Body - Epoxy Powder Coated Steel |

|

|

Chamber – Stainless Steel 304 |

|

|

Insulation – 50mm thick woven mineral wool |

|

|

Shelf -including stainless steel wire shelf |

|

|

optional perforated stainless steel shelf |

|

Electric |

220±10% VAC 50/60Hz 1-Phase |

|

Plug config. |

CEE 7/7 Schuko or BS 1363 or 30 AMP |

Features

|

|

|

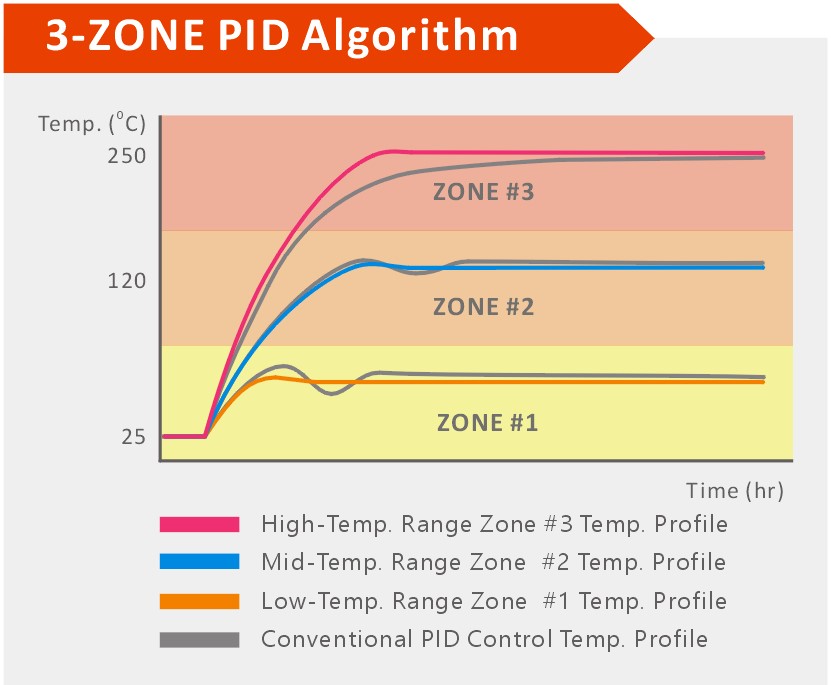

3 GROUP ZONE PID ALGORITHM Complete temperature range is divided into three zones (LOW/MIDDLE/HIGH) and each ZONE has its individual PID Algorithm to provides precise and superior temperature control characteristic of whole temperature range. |

|

|

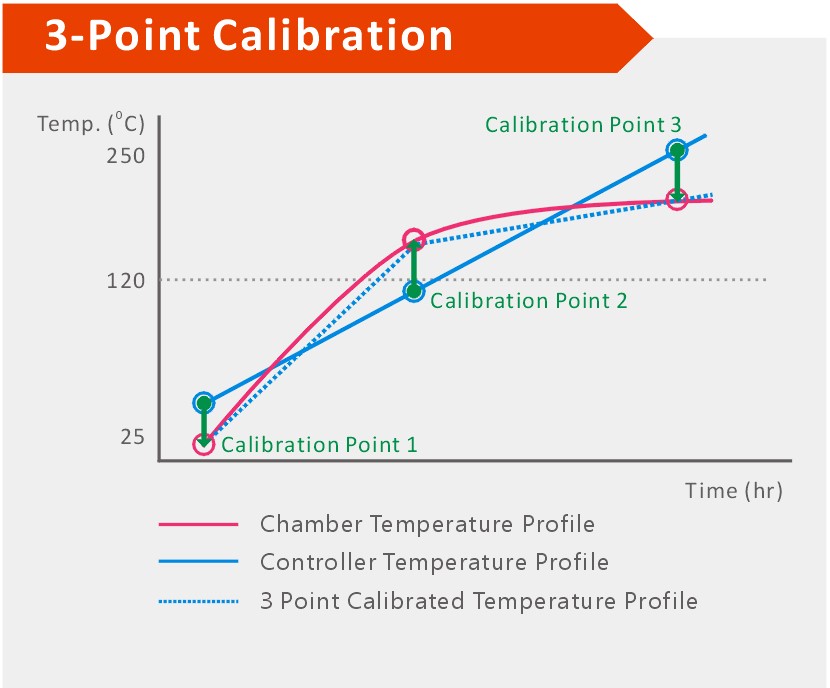

3 POINT CALIBRATION FUNCTION An excellent calibration tool to calibrate chamber at THREE DIFFERENT TEMPEATURE POINTS to adjust multiple TEMPERTURE BIAS to increase temperature accuracy of whole temperature range. |

|

|

|

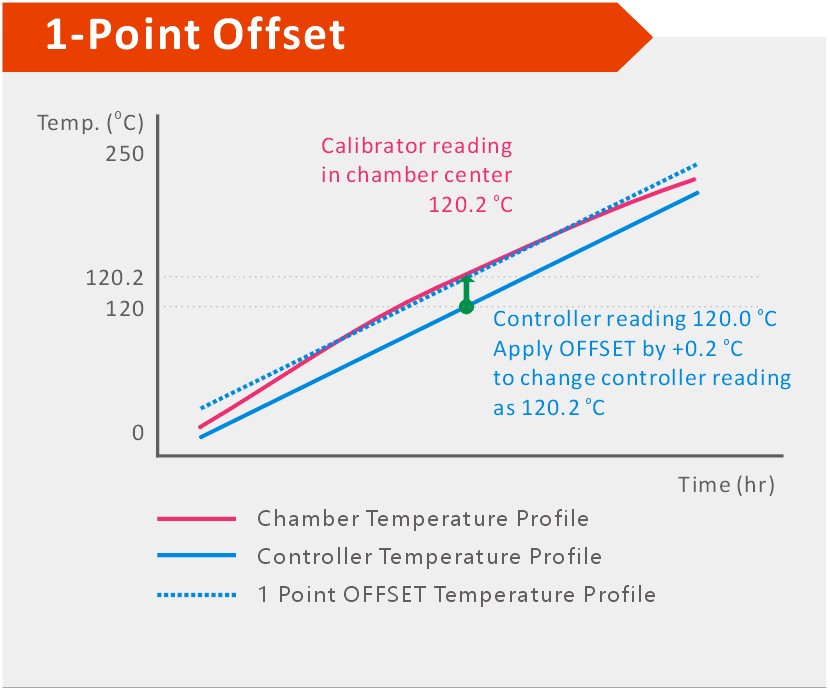

1 POINT OFFSET CALIBRATION Provides simple and easy calibration tool to calibrate chamber at ONE SPECIFIC TEMPERTURE POINT of frequent use. |

| Construction | Chamber | Door Window | ||

|

|

|

||

| Adjustable Shelf | Safety | |||

|

|

Models

|

Art No. |

||||

|

Chamber Volume |

250 L |

372 L |

655 L |

|

|

Dimensions |

Inner |

500 x 500 x 1000 |

610 x 610 x 1000 |

710 x 710 x 1300 |

|

W x D x H mm |

Outer |

895 x 675 x 1360 |

1050 x 785 x 1360 |

1105 x 885 x 1660 |

|

|

Window |

W150 x H460 |

W150 x H460 |

W150 x H615 |

|

Temperature Range |

ambient +10°C to 250°C |

|||

|

Accuracy at 120°C |

± 0.3°C |

± 0.3°C |

± 0.3°C |

|

|

Uniformity at 120°C |

± 1.5°C |

± 2.0°C |

± 3.0°C |

|

|

Heat up time to 120°C |

10 min. |

15 min. |

15 min. |

|

|

No. of Shelves / Max. No. |

3 / 36 |

4 / 36 |

6 / 48 |

|

|

No. of Ventilation damper |

1 |

|||

|

Heater Capacity |

2 x 1.5 kW |

2 x 1.7 kW |

2 x 2.5 kW |

|

|

Power Rating |

14.0 Amp |

16.0 Amp |

23.2 Amp |

|

|

Power Plug |

CEE 7/7 Schuko |

30 AMP |

30 AMP |

|

|

Performance |

|

• Control Temperature Range from ambient +10 oC to 250 oC • Forced air convection for fast drying application • Aero-dynamic chamber designed with circulation blower to achieve superior thermal uniformity • Separate heating compartment located on side wall for contamination free and maintenance free • 50mm thick high thermal efficiency mineral wool with woven aluminum barrier sheet saves energy and less dust |

|

Controller |

|

• DIGITAL MICROPROCESSOR PID TEMPERATURE CONTROLLER • Integrated Digital Microprocessor Control System • Back Light Graphic LCD Display provides user-friendly operating information • UV COATED POLYCARBONATE TOUCH PANEL • Equipped with Capacitive LED Lighting Touch Button provides sensitive touching operation and durability • ENCODER TYPE JOG DIAL • Push to Start and Stop, Rotary turn to change values provides easy and simple user interface • 0.1 oC CONTROL RESOLUTION • Auto-Stop Timer 1 min ~ 99 hour 59 min and alarm • Auto-Start Timer 1 min ~ 99 hour 59 min and alarm • Temperature and Timer Memory Function in frequent use • 3-ZONE PID ALGORITHM • 3-POINT CALIBRATION / 1-POINT OFFSET CALIBRATION • Operating temperature and remaining timer resume in case power outage and restoration • CLASS A PT-100 Ω Sensor • RS-232C PC COMMUNICATION INTERFACE [OPTION]

|

|

Construction |

|

• Durable epoxy powder coated metallic casing • Corrosion resistant Stainless Steel 304 chamber with seamless round cornered edge allows easy cleaning and prevent leakage • Double layered glass window for easy observation of samples • Ventilation damper

|

|

Convenience |

|

• Floor standing large capacity oven provides more through-put and productivity of sample treatment • Double layered tempered safety glass window for easy observation of samples • Stainless Steel 304 Chamber with seamless round cornered edge allows easy cleaning and prevent leakage • Removable and height adjustable shelf by 25mm spacing • Easy-to-open and air-tight one touch door latch • Opening size adjustable ventilation damper • Door switch cut-off heater and blower to protect user from exposure to hot air • Caster for easy transport

|

|

Safety |

|

• PT SENSOR SHORT OR DISCONNECTION AUDIO VISUAL ALARM • DUAL OVER TEMPERATURE CUT-OFF BY CONTROLLER AND INDEPENDENT THERMOSTAT • Controller cut-off heater and AUDIO VISUAL ALARMS ALARM HIGH : +10 oC above set temp. ALARM LOW : -10 oC below set temp. • Independent analog thermostat cut-off heater above set temperature • DOOR OPEN AUDIO VISUAL ALARM • OVER CURRENT CUT-OFF : Electric Circuit Breaker

|

Ordering Information

|

Art No. |

Descriptions |

Capacity |

Elec. Req. |

Net Wt. |

Ship Wt. |

|

JSOF-250T |

Upright Convection Oven |

250 L |

220 VAC 50/60 Hz |

115 kg |

135 kg |

|

JSOF-400T |

Upright Convection Oven |

372 L |

220 VAC 50/60 Hz |

150 kg |

200 kg |

|

JSOF-700T |

Upright Convection Oven |

655 L |

220 VAC 50/60 Hz |

190 kg |

255 kg |

Optional Accessories

|

Art No. |

Perforated Shelf, Stainless Steel 304 |

|

PHS-A06 |

for JSOF-250T W470 x D480 mm |

|

PHS-A11 |

for JSOF-400T W580 x D590 mm |

|

PHS-A15 |

for JSOF-700T W680 x D690 mm |

|

|

|

|

Art No. |

Wire Shelf, Stainless Steel 304 |

|

PHS-B06 |

for JSOF-250T W470 x D480 mm |

|

PHS-B11 |

for JSOF-400T W580 x D590 mm |

|

PHS-B12 |

for JSOF-700T W680 x D690 mm |

|

|

|

|

PHS-A99 |

Shelf Support, Set of 4 |