Vertical Laminar Flow Cabinet (클린벤치)

JSCB-SL 시리즈 Vertical Laminar Flow Safety Cabinet은 작업대 내부에 HEPA 필터로 여과된 공기를 지속적으로 공급하여 미생물 또는 미세한 먼지 등의 오염물질로부터 시료를 보호하도록 설계 되었습니다. 케비넷은 생물안전 1등급의 일반적인 미생물 실험과 무균, 무진 실험을 할 수 있습니다.

jscb-xxxxsl-kor.pdf |

제 품 특 성

|

콘트롤러 |

|

디지털 그래픽 LCD 콘트롤러 -통합형 그래픽 LCD 디스플레이와 정전방식의 터치버튼 -블로어 ON/OFF 및 10단계 풍속 제어 기능 -LED 타입의 조명을 장착하여 조도가 높고 깜박임이 없어 편리하고 전구 수명이 오래감 -자외선 살균 램프 ON/OFF 및 살균 시간 타이머 설정가능 -HEPA 필터 사용 시간 적산기능 및 필터 교체 시기 알람

|

|

특장점 |

|

-케비넷 전면이 3도 기울어지게 설계되어 편안한 작업 자세와 시선이 제공되며, 인체공학적 설계의 팔걸이가 전면에 장착되어 장시간 실험에도 피곤감을 덜 느끼도록 설계 -전면 유리도어는 사용 전후 완전히 밀폐하여 멸균 시 자외선이 외부로 조사 되지 않도록 설계 -내구성이 뛰어난 에폭시 분체 도장 본체 -스테인레스 스틸 304 재질의 작업대는 부식에 강하고 내구성이 뛰어나며 분리형 설계로 실험 전후 살균 및 청소가 용이 -소음과 진동이 작은 블로어 모터 장착으로 쾌적한 작업환경 제공 -PRE-PURGE 기능은 블로어를 켜면 30초간 자동으로 작동하여 사용하지 않는 동안 작업공간 내부에 오염되어 있을 수 있는 공기 전체를 순환시켜 HEPA 필터로 여과하고 작업 준비가 되면 버저를 울려 알림. -POST-PURGE 기능은 블로어를 끄면 30초간 작동하여 사용 후 작업공간 내부에 오염되어 있는 공기 전체를 순환시켜 HEPA 필터로 여과한 후 꺼지도록 설계되어 다음 작업에 발생할 수 있는 오염 발생을 미리 예방 함. -주광색 LED 작업조명 적용으로 긴 내구수명 -253 nm 파장의 자외선 멸균램프 적용 -바퀴가 달려 있어 이동이 편리한 하단 스탠드 기본 제공

|

|

작동성능 |

|

- 무균작업대는 오염된 공기로부터 시료를 보호하고 케비넷은 생물안전 1등급의 일반적인 미생물 실험과 무균, 무진 실험을 하도록 설계 - 프리필터를 통해 흡입된 공기는 HEPA 필터에 여과되어 벤치 내부로 vertical laminar air stream을 형성하여 실험 대상물을 먼지 또는 미생물로부터의 오염에서 보호하고 전면 도어를 통해 실험실 내부로 배출 - HEPA 필터로 여과된 공기는 캐비넷의 위에서 아래 방향으로 일정한 속도의 기류를 형성하여 실험 샘플의 오염, 케비넷 내부의 교차오염, 외부 공기의 유입으로 인한 오염을 방지 - 알루미늄 프레임 Mini-pleated HEPA Filter는 0.3um 크기 이상의 입자를 99.993% ~99.995% 여과 - ULPA Filter는 0.12um 크기 이상의 입자를 99.9999% 여과 (선택사양)

|

|

안전장치 |

|

-전면도어 열림 시 자외선 멸균램프 자동 꺼짐 -HEPA필터 총 누적사용시간 표시 -HEPA 필터 교체시기 설정 및 도달 시 알람 기능 -과전류 차단장치

|

|

디지털 콘트롤러 |

|

|

|

|

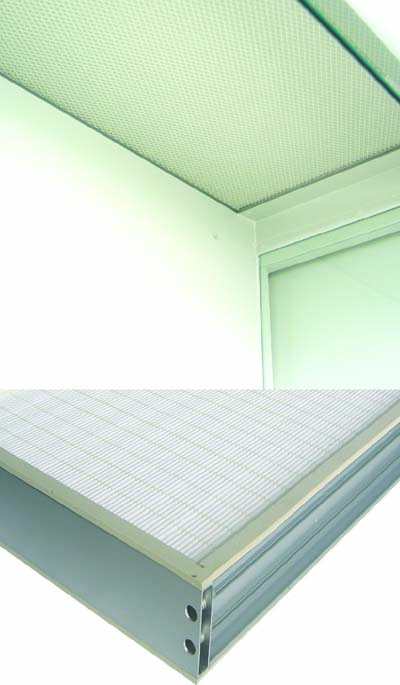

HEPA 필터 |

작업공간 |

조명 및 자외선 살균등 |

편의장치 |

|

|

|

|

|

|

알미늄프레임 미니플리티드 HEPA 필터 여과효율 : 99.993 ~ 99.995% 안전한 필터 보호망 [옵션] ULPA 필터 여과효율 : 99.999% |

작업에 편리한 팔 거치대 청소가 편리한 분리형 작업대 바닥판 유지관리가 편리한 전면 서비스 판넬 스탠드 포함 |

장수명 LED 작업등 253nm UV 살균등

|

전면 강화 유리도어 전원 플러그 가스, 에어 서비스 코크

|

공 통 규 격

|

생물안전등급 |

Biosafety Level 1 Product Protection Only |

|

공기순환구조 |

하강기류형 |

|

풍 속 |

0.3 m/sec. |

|

필 터 |

Aluminum Frame Mini-Pleated HEPA |

|

ULPA Filter [옵션] |

|

|

여과효율 |

HEPA : 99.993% for 0.3 um particle removal |

|

ULPA : 99.999% for 0.12 um particles removal [옵션] |

|

|

콘트롤러 |

디지털 그래픽 LCD 콘트롤러 |

|

9 단계 풍속 제어 |

|

|

재질 |

작업대 : Stainless Steel 304 |

|

본체 : Epoxy Powder Coated Steel |

|

|

살균 |

253nm Germicidal UV Lamp with Timer |

|

편이장치 |

전원 콘센트 x 2개 |

|

가스, 공기 공급 밸브 |

|

|

안전장치 |

과전류 차단 |

|

정격 |

220±10% VAC 50/60Hz 1-Phase |

|

전원플러그 |

220V CEE 7/7 Schuko |

모델 및 사양

|

Model |

||||

|

성능 |

|

|

|

|

|

생물안전등급 |

Biosafety Level 1 Product Protection Only |

|||

|

공기순환구조 |

수직하강기류형 |

|||

|

하강기류속도 |

0.3 m/sec |

|||

|

공기여과효율 |

HEPA filter 99.993~99.995 % for particles > 0.3 um |

|||

|

|

ULPA filter 99.999 % for particles > 0.12 um |

|||

|

소음 |

< 65 dB |

|

|

|

|

작업대 조도 |

1510 Lux |

|

|

|

|

작업등 |

LED 11 watt x 2 ea |

LED 15 watt x 2 ea |

LED 20 watt x 2 ea |

LED 20 watt x 2 ea |

|

자외선 살균램프 253.7 nm |

20 Watt |

30 Watt |

30 Watt |

40 Watt |

|

자외선 조사량 |

7.5 W |

13.4 W |

13.4 W |

19.8 W |

|

|

|

|

|

|

|

규격 |

|

|

|

|

|

작업대 폭 (Width) |

830 mm (3 ft) |

1205 mm (4 ft) |

1490 mm (5 ft) |

1790 mm (5 ft) |

|

내부 (W x D x H mm) |

830 x 550 x 585 |

1205 x 550 x 585 |

1490 x 550 x 585 |

1790 x 550 x 585 |

|

외부 (W x D x H mm) 스탠드제외 |

900 x 800 x 1290 |

1275 x 800 x 1290 |

1560 x 800 x 1290 |

1860 x 800 x 1290 |

|

외부 (W x D x H mm) 스탠드포함 |

900 x 800 x 1970 |

1275 x 800 x 1970 |

1560 x 800 x 1970 |

1860 x 800 x 1970 |

|

|

|

|

|

|

|

콘트롤러 |

|

|

|

|

|

|

통합형 디지털 마이크로프로세서 조절기 |

|||

|

|

그래픽 LCD 디스플레이 |

|||

|

|

정전식 터치 발광 스위치 |

|||

|

|

10단계 풍속 조절 |

|||

|

|

Fan ON/OFF 기능과 풍속 조절 기능 |

|||

|

|

LED 작업등 점멸 스위치 |

|||

|

|

UV 멸균등 점멸 스위치 |

|||

|

|

사용자 설정 가능한 UV 멸균등 타이머 |

|||

|

|

HEPA 필터 사용시간 표시 및 교체시기 알람 |

|||

|

|

|

|

|

|

|

안전장치 |

|

|

|

|

|

|

과전류 차단장치 |

|||

|

|

전면 도어 열림 시 UV 멸균램프 자동 꺼짐 장치 |

|||

|

|

HEPA 필터 교체 알람 |

|||

|

|

|

|

|

|

|

재질 |

|

|

|

|

|

작업대 |

분리형 설계의 SUS 304 (AISI 304) 작업대 |

|||

|

본체 |

SPCC 열연강판 / 에폭시 분체도장 |

|||

|

전면 유리도어 |

강화유리 슬라이딩 도어 |

|||

|

|

|

|

|

|

|

편의장치 |

|

|

|

|

|

작업등 LED |

11 watt x 2 ea |

15 watt x 2 ea |

20 watt x 2 ea |

20 watt x 2 ea |

|

자외선살균등 |

20 watt |

30 watt |

30 watt |

40 watt |

|

|

220 V 용 방우형 전원콘센트 x 2 ea |

|||

|

|

서비스밸브 x 2 ea |

|||

|

|

|

|

|

|

|

정격 |

|

|

|

|

|

정격전압 |

220 ± 10% VAC |

|||

|

주파수 |

50 / 60Hz |

|||

|

소비전력 |

200 Watt 0.9 amp |

350 Watt 1.6 amp |

350 Watt 1.6 amp |

375 Watt 1.7 amp |

|

상 |

1 Phase |

|||

|

전원플러그 |

220V용 CEE 7/7 Schuko |

|||

|

|

|

|

|

|

|

사용환경 |

|

|

|

|

|

온습도 |

5oC - 40 oC, < 80% RH |

|||

|

|

|

|

|

|

|

포장규격 |

|

|

|

|

|

선적규격 (W x D x H mm ) |

950 x 940 x 1650 |

1330 x 940 x 1650 |

1610 x 940 x 1650 |

1940 x 940 x 1650 |

|

포장방법 |

Carton on a wooden palette |

|||

|

순중량 |

130.0 kg |

182.0 kg |

200.0 kg |

267.0 kg |

|

선적중량 |

180.0 kg |

213.0 kg |

250.0 kg |

290.0 kg |

주문정보

|

Art No. |

Descriptions |

Width |

Elec. Req. |

Net Wt. |

Ship Wt. |

|

JSCB-900SL |

Vertical Laminar Flow Safety Cabinet |

830 mm |

220 VAC 50/60 Hz |

130 kg |

180 kg |

|

JSCB-1200SL |

Vertical Laminar Flow Safety Cabinet |

1205 mm |

220 VAC 50/60 Hz |

170 kg |

210 kg |

|

JSCB-1500SL |

Vertical Laminar Flow Safety Cabinet |

1490 mm |

220 VAC 50/60 Hz |

200 kg |

250 kg |

|

JSCB-1800SL |

Vertical Laminar Flow Safety Cabinet |

1790 mm |

220 VAC 50/60 Hz |

230 kg |

290 kg |

선택사양

|

Art No. |

ULPA Filter 옵션 (HEPA 필터 대신 ULPA 필터가 장착 됩니다) |

|

OHF-U05 |

for JSCB-900SL |

|

OHF-U06 |

for JSCB-1200SL |

|

OHF-U07 |

for JSCB-1500SL |

|

OHF-U08 |

for JSCB-1800SL |